QC TESTING OF POLYMERS FOR MOLECULAR WEIGHT AND MOLECULAR WEIGHT DISTRIBUTION

PROBLEM

Producers of polymers need a convenient, rapid technique for confirming the polymers approximate molecular weight/molecular weight distribution during production. Traditional techniques such as gel permeation chromatography (GPC) are not ideal because they are time consuming and require dissolving the polymer in a suitable yet safe solvent.

SOLUTION

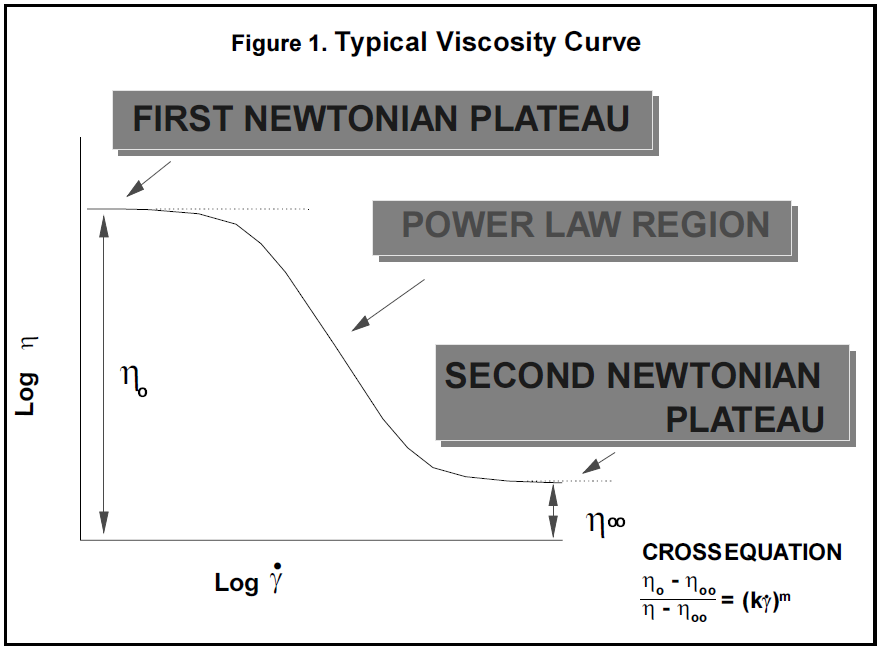

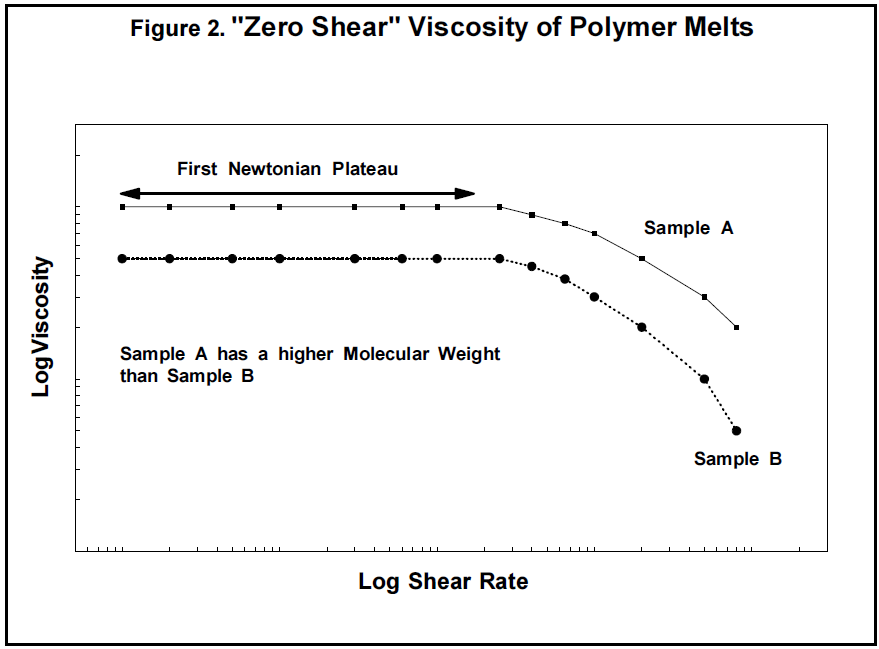

Controlled stress rheology, which measures the flow of materials, provides an alternative to GPC for rapidly characterizing polymers. Rheological evaluation is based on the fact that most non-Newtonian fluids like molten polymers have a defined flow profile which can be modeled by the Cross equation (Figure 1). In simple terms, at low shear rates molten polymers have a constant viscosity and at high shear rates they have another constant value of viscosity (although lower in value than at low shear rates). These two viscosity plateaus are connected by a range of shear rates where the behavior of the polymer is shear thinning, i.e., the viscosity reduces as a function of the shear stress/shear rate. The shear rate ranges in which these three different types of behavior occur is dependent upon the material. However, for polymer melts, the viscosity of the material in the low shear plateau is related to the molecular weight of the polymer. The higher the molecular weight, the higher the viscosity plateau - commonly termed the Zero Shear Viscosity (see Figure 2).

Hence, if suitable standards covering the desired molecular weight range are available, they can be used to construct a calibration curve which can subsequently be used to determine if a sample from production is acceptable. For example, assuming Samples A and B in Figure 2 represent the boundaries of acceptable molecular weight, production samples which yield a curve between these two standard curves would then rapidly be judged acceptable.

This rheology evaluation of molecular weight is based on placing the polymer in the rheometer, heating it rapidly to the desired temperature above the melt, and then performing a single creep test at an appropriate stress which would generate a point on the zero shear plateau. [The analysis of the creep curve provides a viscosity value.] The complete test can be performed in about 10 minutes assuming a suitable heater is used. An induction-type heater which covers the range -100 to 400°C at rates up to 2°C/second with an accuracy and stability of ±0.1°C is optimal for this test. In addition to keeping the time of testing short, rapid heating under an inert purge (e.g., nitrogen) assures no polymer degradation occurs during the test.

Acknowledgment: This brief is based on studies done by John Kelly, TA Instruments (UK).